|

Rotary Cutting Rules |

|

|

5 and 6 Tooth:

Ideal for diecutting high density foam products, It works well on film and in other applications where you are cutting into air or into a slot.

Thickness |

Heights |

2pt. (0.71mm) |

23.80mm (0.937’’) – 101.6mm (4.00’’) |

3pt. (1.07mm) |

|

4pt. (1.42mm) |

|

6pt. (2.14mm) |

76.2mm (3.0’’) max. |

8pt. (2.84mm) |

50.8mm (2.0’’) max. |

|

|

|

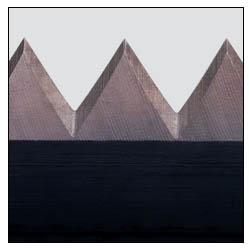

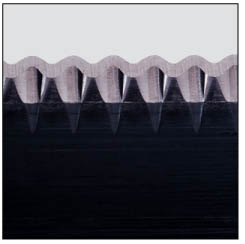

Deep ‘V’:

Extremely sharp teeth with deep gullets achieve excellent performance with minimum pressure, when working with film, foam and even some specialty paper products such as thinner honeycomb. Available with 8, 10, 13, 16 TPI.

Thickness |

Heights |

2pt. (0.71mm) |

15.88mm (0.625’’) – 101.6mm (4.00’’) |

3pt. (1.07mm) |

|

4pt. (1.42mm) |

|

6pt. (2.14mm) |

76.2mm (3.0’’) max. |

8pt. (2.84mm) |

50.8mm (2.0’’) max. |

|

|

|

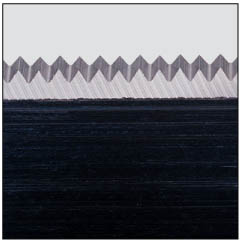

2.7 and 4.6 tooth:

Originally custom designed for cutting plastic bags-now proven to be ideal for cutting foam or film.

Thickness |

Heights |

2pt. (0.71mm) |

23.80mm (0.937’’) – 101.6mm (4.00’’) |

3pt. (1.07mm) |

|

4pt. (1.42mm) |

|

6pt. (2.14mm) |

76.2mm (3.0’’) max. |

8pt. (2.84mm) |

50.8mm (2.0’’) max. |

|

|

|

Klean Kut:

It is available in 8, 10 and 13 tooth versions. Standard 8 tooth Klean Kut is produced from a harder rule for better wear resistance. It is an excellent choice for tough lead edge applications.

Klean Kut is a rule designed to cut with minimum pressure and penetration on both medium and heavy board.

Thickness |

Heights |

2pt. (0.71mm) |

23.80mm (0.937’’) – 101.6mm (4.00’’) |

3pt. (1.07mm) |

|

4pt. (1.42mm) |

|

6pt. (2.14mm) |

76.2mm (3.0’’) max. |

8pt. (2.84mm) |

50.8mm (2.0’’) max. |

|

|

|

Prism:

Combines the benefits of a longer shaved bevel for improved release and with an induction hardened edge for longer life. It reduces edge crush and is excellent for medium to heavy boards. |

|

|

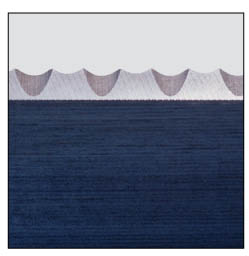

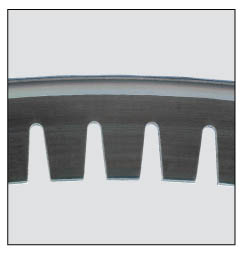

Scalloped:

A rule with an extremely durable tooth that works well in the most demanding of applications the 8 tooth centre bevel leaves a clean scalloped edge on solid fiber substrates, rubber and certain plastics and a straight edge on corrugated material.

- Durable tooth design

- Excellent for solid fiber

- Leaves a safely edge on corrugated

- Great for rotary and flat application

Thickness |

Heights |

2pt. (0.71mm) |

10mm (0.394") – 50.8mm (2.00") |

3pt. (1.07mm) |

10mm (0.394") – 101.6mm (4.00") |

4pt. (1.42mm) |

12mm (0.472") -101.6mm (4.00") |

6pt. (2.14mm) |

76.2mm (3.00’’) max. |

8pt. (2.84mm) |

50.8mm (2.00’’) max. |

Curved diameters available 203.2mm (8.00") and above. |

|

|

11, 16 and 20 tooth:

11 teeth are ideal for foam and composite materials that are likely to stretch prior to cutting. It is ideal for foam and composite materials.

16 teeth are suitable for displays and applications where edge appearances are critical.

20 teeth give a clean edge and also perform well on lighter boards and micro flute.

Thickness |

Heights |

2pt. (0.71mm) |

10mm (0.394") – 50.8mm (2.00") |

3pt. (1.07mm) |

10mm (0.394") – 101.6mm (4.00") |

4pt. (1.42mm) |

12mm (0.472") -101.6mm (4.00") |

6pt. (2.14mm) |

76.2mm (3.00’’) max. |

8pt. (2.84mm) |

50.8mm (2.00’’) max. |

Curved diameters available 152.4mm (6.00") and above. |

|

|

Euro-Cut

It has a shaved edge symmetrically ground, center bevel rule that incorporates Nat-Ex hardening technology. The combination of the Nat-Ex edge on a 345 Hv body provides superior bendability along with extended die life.

Its unique 8 and 10 tooth designs reduce cutting pressure on heavy and wet board which improves stripping and extends anvil life. The shaved edge cuts cleanly through all grades of board which reduces both edge crush and paper dust.

It works equally well around or across the cylinder. The exceptional cut ability of this rule even allows you to use the same height cutting rule in both directions.

Euro-Cut is available in a harder version (500 Hv) for tough lead and trail edge applications.

Thickness |

Heights |

3pt. (1.07mm) |

15mm (0.590") – 40mm (1.575") |

4pt. (1.42mm) |

15mm (0.590") -101.6mm (4.00") |

6pt. (2.14mm) |

19.05mm (0.75’’) – 76.20mm (3.00") |

Curved Diameters available 203.2mm (8.00") and above. |

|

|

Standard 8, 10 and 12 Tooth

They have a smooth shaved bevel and are symmetrically ground to exactly standards. They are available in all rotary heights and can be edge hardened for even longer life.

The 8 Tooth has an aggressive tooth configuration and is used typically for long horizontal cuts. It's an excellent choice when diecutting heavier board grades such as double as well.

The 10 Tooth is the most versatile cutting rule. This radius gullet rule provides an excellent combination of cut ability and bendability across a wide range of board grades. It's the world's most widely used rotary cutting rules.

The 12 Tooth is the original high performance rule.

Thickness |

Heights |

2pt. (0.71mm) |

15mm (0.590") – 50.8mm (2.00") |

3pt. (1.07mm) |

15mm (0.590") – 101.6mm (4.00") |

4pt. (1.42mm) |

15mm (0.590") -101.6mm (4.00") |

6pt. (2.14mm) |

19.05mm (0.75") -76.20mm (3.00’’) |

8pt. (2.84mm) |

19.05mm (0.75") -50.80mm (2.00") |

Curved Diameters available 152.4mm (6.00") and above. |

|

|

|

|

|

Arrowhead

Standard 8 teeth Arrowhead combines the benefits of a longer shaved bevel for improved release with an induction hardened edge for longer life. It reduces edge crush and is excellent for medium to heavy boards.

10 teeth Arrowhead has all the benefits of standard Arrowhead plus the fine tooth pattern gives a smoother cut on lighter boards.

For long runs on medium to heavy board it is an excellent rule to use around the cylinder with standard 8 teeth Arrowhead across the drum.

Thickness |

Heights |

2pt. (0.71mm) |

10mm (0.394") – 50.8mm (2.00") |

3pt. (1.07mm) |

10mm (0.394") – 101.6mm (4.00") |

4pt. (1.42mm) |

12mm (0.472") -101.6mm (4.00") |

6pt. (2.14mm) |

76.2mm - (3.00’’) max. |

8pt. (2.84mm) |

50.80mm - (2.00")max. |

Curved Diameters available 177.8mm (7.00") and above. |

|

|

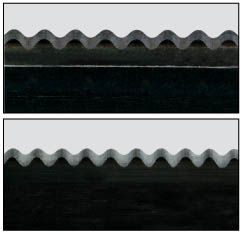

SST

Serrated Scalloped Tooth is an 8 pitch rule designed to produce a safety edge on corrugated that reduces paper cuts in hand packaging operations.

It can be used as a multi-purpose rotary rule since it produces an excellent balance of cutability, wear and edge appearance.

Thickness |

Heights |

2pt. (0.71mm) |

10mm (0.394") – 50.8mm (2.00") |

3pt. (1.07mm) |

10mm (0.394") – 101.6mm (4.00") |

4pt. (1.42mm) |

12mm (0.472") -101.6mm (4.00") |

6pt. (2.14mm) |

76.2mm - (3.00’’) max. |

8pt. (2.84mm) |

50.80mm - (2.00")max. |

Curved Diameters available 203.2mm (8.00") and above. |

|

|

Steel to Steel

A self-levelling rule that utilizes a softer intermittent zone as opposed to a thinner base, to form a compression zone.

It is available in straights and curves to all standard diameters. |

|

|

Shallow profile

It has the shallowest gullet of any National serrated rule. Though primarily a center bevel product ground from one side, Shallow profile can be manufactured with a symmetrically ground center bevel or a side bevel.

It can be used in both flat and rotary applications. Also it works well on fabrics, rubber, plastics and other materials that require diecutting with minimal penetration.

The ability to cut with less penetration makes shallow profile an excellent choice when cutting against a belt or a non-oscillating anvil.

- Cuts with less penetration

- Good when cutting against a harder cutting pad

- Available in al heights and thicknesses

- Available in most standard rotary sizes

Thickness Available |

Heights Available |

2pt. (0.71mm) |

0.312" (7.92 mm) – 4.000" (101.6mm) |

3pt. (1.07mm) |

6 Pt. – 3.000" max. |

4pt. (1.42mm) |

8 Pt. – 2.000" max. |

6pt. (2.14mm) |

|

8pt. (2.84mm) |

|

Curved ID Available |

|

7.000" (177.8 mm) and above. |

|

|

|

|

|

|

|

|

|